Kia Cadenza YG: Engine Control System / Knock Sensor (KS) Description and Operation

Kia Cadenza YG 2016-2021 Service Manual / Engine Control / Fuel System / Engine Control System / Knock Sensor (KS) Description and Operation

| Description |

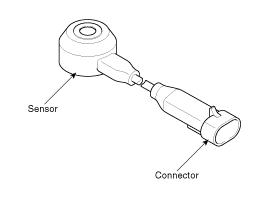

Knocking is a phenomenon characterized by undesirable

vibration and noise and can cause engine damage. The two Knock Sensor

(KS) are installed inside the V-valley of the cylinder block and senses

engine knocking.

When knocking occurs, the vibration from the cylinder block is applied as pressure to the piezoelectric element.

When a knock occurs, the sensor produces voltage signal. The

ECM retards the ignition timing when knocking occurs. If the knocking

disappears after retarding the ignition timing, the ECM will advance the

ignition timing. This sequential control can improve engine power,

torque and fuel economy.

Inspection 1. Check the signal waveform of the CMPS and CKPS using the GDS. Specification: Refer to “Wave Form” Removal • DON''T remove the camshaft position sensor while the engine is running or right after engine is turned off.

Specification ItemSpecificationCapacitance (pF)950 ~ 1,350Resistance (MΩ)4.87

Other information:

Kia Cadenza YG 2016-2021 Service Manual: Schematic Diagrams

C

Kia Cadenza YG 2016-2021 Service Manual: General Safety Information and Caution

Instructions When Handling Refrigerant 1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves. 2. It is standard practice to wear goggles or glasses to protect your eyes, and gloves to protect your hands.

Categories

- Manuals Home

- Kia Cadenza Owners Manual

- Kia Cadenza Service Manual

- Alternator Schematic Diagrams

- Driveshaft and axle

- Engine Mechanical System

- New on site

- Most important about car

Copyright © 2026 www.kcadenzavg.com - 0.0328